Automation Spirit AllianceEfficient solutions for automation of your enterprise

Automation of enterprises from any sector

Design, production, and installation of consoles and control cabinets

Development of integrated control systems and individual modules

Qualified technical support of implemented projects

About us

We are a progressive engineering company that offers modern solutions for the automation of enterprises in order to increase their productivity and profitability.

ASA is a dynamically developing engineering company. In our work, we pay special attention to automation and computerization of technological processes within the framework of Industry 4.0. ASA engineers create IT products and solutions for a variety of industries.

ASA is represented on the international market. We have successfully completed projects on the development and implementation of Automated Process Control Systems (APCS) in different countries, including China, India, Colombia, Brazil, Poland, and Kazakhstan.

About Us

APCS (Automation process control systems)

This is the main activity of the company. We design, manufacture and implement effective management systems for enterprises from various fields of activity.

We offer the realization of a full cycle of industrial automation, consisting of several stages:

- Enterprise equipment audit;

- Development of project documentation (basic and detailed engineering);

- PLC/HMI/SCADA software development;

- ACSP equipment manufacturing, supply of assembly parts;

- Assembly work at the enterprise;

- Equipment commissioning;

- Warranty/post-warranty service.

At your request, we can develop a turnkey solution or perform individual project processes.

Digitalization within the framework of Industry 4.0

Within the framework of the global Industry 4.0 program, we are digitally transforming enterprises with the aim of:

- Integrating disparate production equipment into a single system;

- Formation of structured data flows for further analytics;

- Monitoring and optimization of energy consumption within the sections of the enterprise;

- Integrating APCS modules with ERP systems for the formation of accounting documentation.

Industrial Internet of Things (IIoT) is a part of Industry 4.0 and involves the installation of sensors to collect information on industrial equipment, the creation of data hubs, and their processing using appropriate software.

Benefits of choosing ASA

A team of first-class specialists united by the spirit of automation

The best engineers and programmers with over 10 years of experience will work on your projects.

Successful experience in the global market

We have implemented automated systems in China, India, Colombia, Kazakhstan, Poland, Ukraine, and other countries.

Timely technical support

We provide remote technical support anywhere in the world through TeamViewer, AnyDesk, and other remote access software. On request, our engineers can travel to the site, wherever it is located.

Our mission

Our mission is to make each enterprise work with accuracy, higher quality, and profitability. We constantly monitor trends in our industry and collaborate with leading technology companies.

ASA is an international alliance of high-tech industrial companies, which actively develop their business around the world and provide new opportunities for your business.

The ASA ideology is based on four main principles:

• Constant development

• Effective exchange of experience

• Process optimization is the key to profitability

• Creation without destruction

Our Mission

Our company's mission is to make each enterprise work with accuracy, higher quality, and profitability. The ASA ideology is based on 4 main principles:

Constant development

We are always looking for new solutions and improving what we have already created. We research the market sectors and study current trends. The team at ASA provides technologies that are specifically tailored to solve relevant problems.

Effective exchange of experience

ASA (Automation Spirit Alliance) is an alliance of automation companies, within which there is a constant exchange of valuable information. Because of this, the achievements of one representative of the alliance become the property of the entire group. This approach makes it possible to quickly find solutions to complex problems.

Process optimization is the key to profitability

Any enterprise can work better even without cardinal changes. We optimize the operation of production facilities so you spend less time, effort, and money to achieve your goals.

Creation without destruction

Many of the company's projects are aimed at reducing the environmental damage caused by enterprises. In our projects, we also take into account, among other tasks, the global problem of greenhouse gas emissions.

Our history

The path of the company’s development has passed through dozens of large-scale and medium-scale projects in different parts of the world. We believe there are even more serious challenges ahead, which we are ready to take on.

We have successfully implemented a large number of projects in different countries of the world and in a variety of industries, from agricultural enterprises and wastewater treatment plants to the chemical, energy, metallurgical and defense sectors.

Our History

The path of the company's development has passed through dozens of large-scale projects in different parts of the world. But there are even more serious challenges ahead, which we are ready to take on.

Foundation of Automation Spirit Alliance

Development of a control system for the heavy oil refining machine.

*EBRD sponsored project

Development and implementation of ASA-TITAN Building Climate Automated Control System

Development and implementation of the Integrated Control System (ICS) AIR SHIELD designed to protect people and sites from malicious drones.

WHAT IS NEXT …?

Our partners

Therefore, we are always confident in timely deliveries and high-quality components.

Already interested?

Ready to provide our services right now

Services

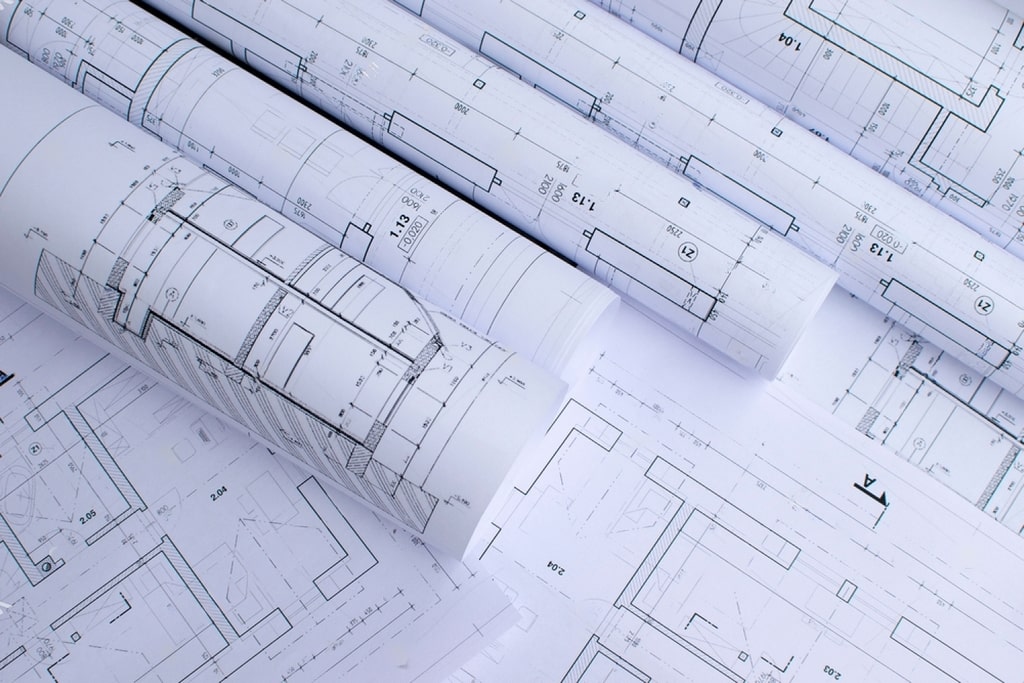

DEVELOPMENT OF PROJECT DOCUMENTATION

Our project documentation provides the Customer with answers to key questions:

• What equipment will be supplied…

Development of design documentation

Our project documentation provides the Customer with answers to key questions:

- What equipment will be supplied;

- What kind of work will be carried out;

- Estimated cost of the project.

When designing, special requirements are necessarily taken into account, such as explosion and fire hazards, environmental protection, and operational safety.

All projects comply with state, regional, and industry standards, as well as internal standards of the enterprise.

For the development of project documentation, we use the following formats: AutoCAD, Kompas 3D, EPlan Electric P8, MS Word, MS Excel, MS Visio.

SOFTWARE DEVELOPMENT

Our principle in software development is open-source code. We transfer to the Customer all projects and program codes with their description…

Software development

Our principle in software development is open-source code. We transfer to the Customer all projects and program codes with their description. If necessary, password protection is set for reading and changing the program. We provide software development services for automated process control systems of the following types: PLC / HMI / SCADA / Cloud applications.

PLC

This type of software is created in a development environment for a particular type of PLC according to the European standard EN 61131. Depending on the automation platform, various development environments are used, such as Simatic Step7, TIA Portal, Unity Pro, CoDeSys, Cimplicity Machine Edition, CScape, etc.

The PLC software performs the following functions:

- Interrogation of digital and analog inputs at the local PLC rack, expansion rack, and remote stations;

- Primary conversion of input signals (debounce elimination and validation, analog signal conversion, evaluation of warning and alarm limits;

- Execution of fast subroutines in accordance with the algorithms of emergency protection;

- Verification of interlocks;

- Execution of basic control algorithms, including PID controllers;

- Providing information to the upper level, and receiving commands from the upper level;

- Issuance of control signals to discrete and analog outputs of local PLC racks, expansion racks, and remote I/O stations.

- Communication exchange via digital interfaces ProfibusDP, ModbusRTU, ModbusTCP, etc.

We own the necessary licenses for software tools, so the cost of development includes only the labor intensity and the author's work on the development of the application software. However, on the customer’s request, instrumental software with all necessary licenses can be supplied, allowing the Customer to make changes in the application program independently.

SCADA

SCADA system software is developed using the SCADA package from one of the well-known manufacturers. Depending on the automation platform, different packages are used, such as InTouch, WinCC, Cimplicity Plant Edition, and Vijeo Citect. It is possible to mix PLC and SCADA from different manufacturers by using industry-standard data transfer protocols.

The SCADA system software performs the following functions:

- Provides the operator with an interface for working with the automated process control system (APCS) in the form of technological mnemonic diagrams, control panels, and information windows;

- Information is provided in visual-graphical, numerical, tabular, and chart form;

- Information exchange with PLC;

- Archiving information and event logs, and viewing archives;

- Generation of reporting forms and documentation;

- User rights management.

SCADA system software operates under the Windows operating system with a runtime license. The license is purchased separately for each SCADA-system workstation. The cost of a license depends on the number of points (tags, input/output channels) in the system, the need to purchase specific drivers, the need for additional services, such as full-function archiving, the provision of a WEB interface, etc.

HMI

Operator panel software is designed to provide a human-machine interface on industrial LCD panels embedded in operator stations. Depending on the type of operator panel, various software products for software development are used, such as TiaPortal, WinCC Flexible, Vijeo Designer, etc.

The runtime license and operating system are included in the cost of the operator panel itself, and some development packages are free or shareware. Often, the software includes such services as a WEB interface, the major industrial protocols for digital interfaces, an OPC server, and others.

Operator panel software functions are similar to those of SCADA systems, with the difference that they provide more simplified capabilities and, as a rule, archiving and reporting are not used on panels.

Cloud Applications

ASA develops, by order of the client, applications for remote access to its APCS from devices via the WEB interface, as well as Android and iOS applications. For this purpose, standard cloud technologies are used, which PLC, HMI, and SCADA manufacturers integrate into their products. Thus, our client receives a remote access application to the APCS without the need to purchase a remote access license, only the development of the application for a particular APCS is paid.

All software for the designed APCS is tested using mathematical modeling tools on a test bench, which presents several types of PLCs and operator panels. This testing allows us to eliminate all errors and adjust the operation of the system even before the software is installed on the Customer's equipment.

CONSTRUCTION AND ASSEMBLY WORK

Construction and assembly work (CAW) is an integral part of the implementation of the APCS and includes the following works at the Customer’s site…

Construction and installation work

Construction and assembly work (CAW) is an integral part of the implementation of the APCS and includes the following works at the Customer's site:

- installation of cable structures;

- installation of cabinets, racks, and panels;

- installation of devices on technological equipment, and pipelines;

- connection of impulse lines to devices;

- laying and connecting cables, testing;

- carrying out tests (impulse lines, insulation resistance, grounding);

- issue executive documentation.

We can perform the full range of construction and assembly work, carry out supervision (supervision of installation), or combine both options (for example, supervision of instrumentation, cable lines, and installation, connection of equipment).

COMMISSIONING WORK

Commissioning work (CW) is a very important stage of the APCS implementation. Since we often have to work with unique (innovative) projects…

Commissioning works

Commissioning work (CW) is a very important stage of the APCS implementation. Since we often have to work with unique (innovative) projects, it is during the commissioning stage the APCS is configured according to the needs of the Customer. The commissioning work includes the following activities:

- Voltage supply to the APCS equipment;

- Cranking mechanisms in local mode;

- Testing docking protocols with third-party equipment via digital communication channels;

- Cross-checking the passage of all signals;

- Cranking of mechanisms in manual remote mode;

- Testing the control program and algorithms;

- Carrying out tests;

- Personnel training;

- Operational documentation.

PLCs pass a series of tests for compliance with international standards: IEC 60947-1:2017; IEC 55022:2017; IEC 55024:2017; IEC 61000-6-2:2015; IEC 61000-6-4:2016.

All APCS equipment is preliminarily tested on a test bench in our company's laboratory. This testing allows to reduce the time of commissioning work at the Customer's site and thus reduces the downtime of the equipment.

Equipment

Control panels

Control cabinets

Test benches

ASA systems and technologies

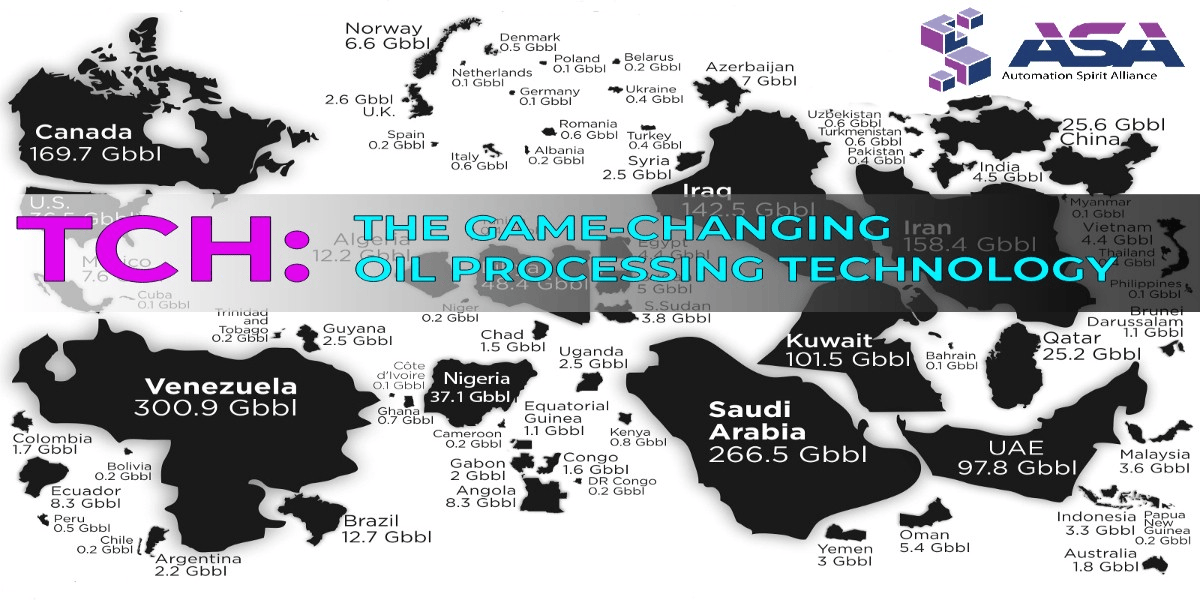

TCH-technology

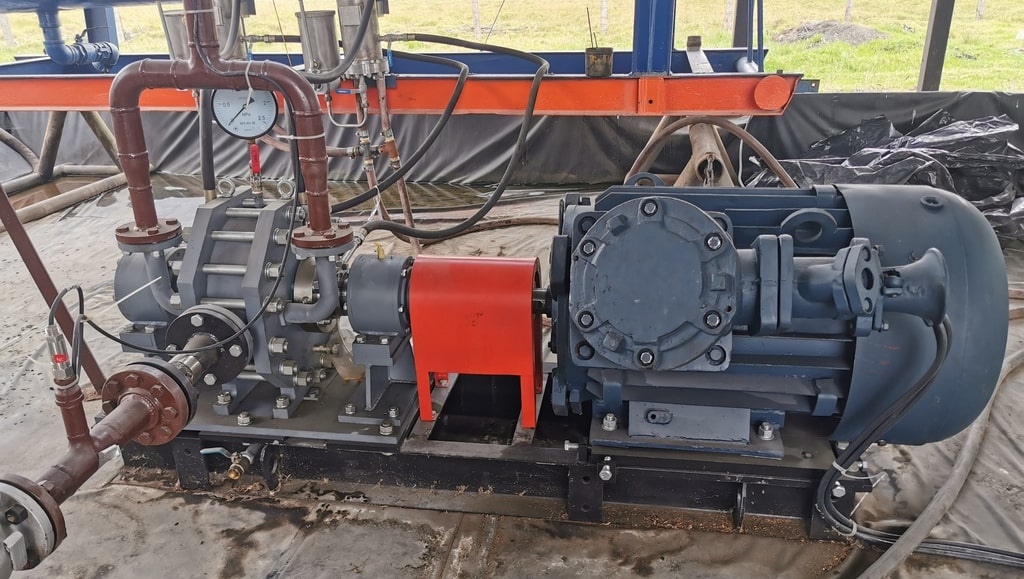

Cavitation treatment of crude oil

TCH-technology

Our company is a strategic partner in the development and implementation of equipment designed for cavitation treatment of heavy oil (TCH- technology). This technology is created to modify the characteristics of crude oil in order to transfer it from an extra-heavy/heavy class to a heavy/medium class, by reducing its viscosity and density, for its further use and transportation.

The economic effect is achieved through:

- increasing the total amount of marketable oil;

- reducing the cost of its transportation;

- increasing the yield of light oil products.

Technology Benefits

- Reducing the density and viscosity of extra-heavy/heavy crude oil without the use of diluents such as naphtha;

- Low raw-materials transportation cost compared to dilution with naphtha;

- Production increase in oil volume from 6% to 10% (due to a decrease in oil density);

- Increasing the yield of light fractions;

- Increased production in modular form.

This technology has been successfully implemented at several large oil-producing enterprises in Colombia (South America). We are ready to provide more detailed information about the advantages of this technology and will be glad to cooperate with you in a mutually beneficial way. For more information, please contact us.

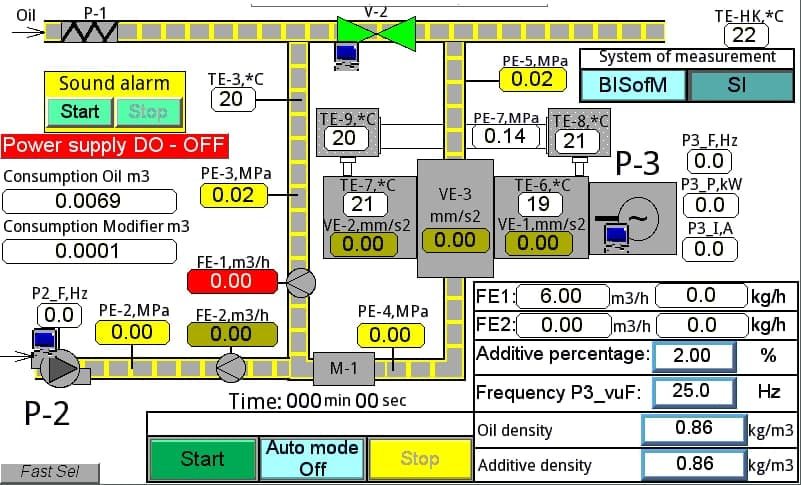

ASA-TITAN

Boiler house control system

ASA-TITAN

ASA-TITAN integrated control system is smart climate control for large buildings with additional security features. Automatic control of all processes related to the management of boilers and pumps is the main task of our complex. Thanks to the use of precise mathematical algorithms, sensitive sensors, and the absence of a human factor, it is possible to achieve maximum efficiency in the operation of building life support systems.

ASA-TITAN is responsible for temperature conditions, adapting them to the user's requirements. There are several extremely useful options:

- Programming of control modes: automatic — on the set temperature in the building; according to the schedule of approximation of coolant temperatures depending on the outside air temperature, and Semi-automatic — maintaining the temperature of the coolant set by the operator.

- Management of the load level, depending on the day of the week and time of the day. Can be configured in automatic and semi-automatic mode.

- Automatic shutdown of equipment when registering an emergency, as well as when exceeding the load limits set by the operator.

- Maintaining the desired temperature of coolant with minimal energy costs to protect the system from freezing.

- Self-diagnosis of the system, self-detection of damage. Accompanied by an alert system for quick troubleshooting.

- Archiving and storage of logs functioning with constant access to data.

For the convenience of the user, remote control is implemented from anywhere in the world. You can use a laptop, smartphone, tablet, and other devices with Internet access.

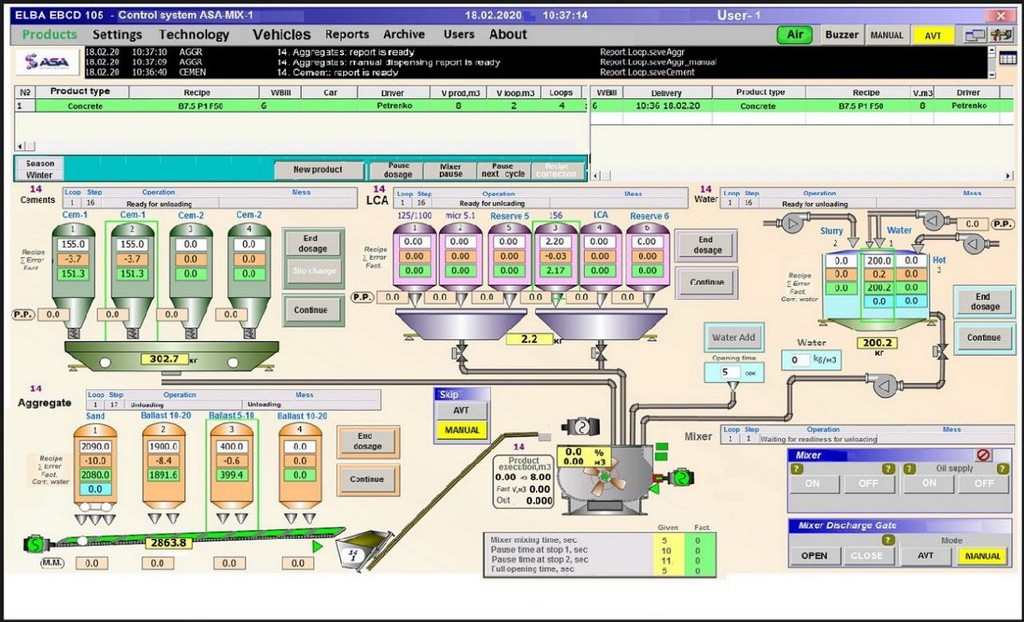

ASA-MIX-1

Concrete plant automation system

ASA-MIX-1

This system is a turnkey solution for concrete producers. ASA-MIX-1 automation system adapts to any type of equipment, increases production efficiency, and provides accurate accounting of materials, eliminating theft.

ASA-MIX-1 includes a computer-based operator's workstation with special software that allows control of the process of ready-mixed concrete preparation and generates predetermined reports, as well as a programmable controller that provides control of the production process.

Adaptive software algorithms allow working with any type of equipment, regardless of the manufacturer. ASA-MIX-1 has been successfully implemented and shows excellent results on SIMEM, Stetter, MEKA, and ELBA equipment.

The implementation of ASA-MIX-1 Concrete plant automation system allows to significantly increase the accuracy of raw material dosing, improve product quality and reduce ready-mixed concrete production cost.

ASA AIR SHIELD

UAV Detection and suppression system

ASA AIR SHIELD

The integrated system for detecting and suppressing unmanned aerial vehicles (UAV) is designed to protect the airspace above the industrial site (perimeter) and zones from UAV intrusion in order to exclude unauthorized access to the protected areas.

The goals of implementing the integrated protection system:

- Detection of unauthorized UAVs in the perimeter airspace and on approach courses;

- Formation of alarm signals and notification of the relevant services about the unauthorized occurrence of the UAV;

- UAV signal suppression by interference in the radio frequency range of the UAV operation;

- Collection and archiving of information on the server about the state of the perimeter airspace and display on the operator's workstation;

- Integration with an adjacent system - a perimeter security system.

The integrated system for the detection and suppression of UAVs includes the following modules:

- An integrated platform for radio detection and suppression of drones. The radio detection and suppression system includes:

- Aeroscope;

- a sectoral UAV detection and jamming system;

- a system of optical and acoustic all-round visibility and identification of the location of the UAV;

- integrated control system AIR SHIELD.

Do you have any questions?

Ready to answer them

Our Portfolio

APCS for the technology of synthesis and modification of rubbers

Polish company Jakusz Sp. z O.O. invited ASA to develop the process control system for the synthesis of polymer rubbers and their modification.

Developing APCS for an acid-recovery plant

Design and construction of APCS of a plant for the regeneration of nitric and sulfuric acid using the technology of the German company PLINKE

TCH-technology – Cavitation treatment of hydrocarbons

Treatment Cavitation Hydrocarbons (TCH-technology) is a technology that allows significant changes in the characteristics of crude oil (density, viscosity, and content of light fractions)

ASA-MIX-1 Concrete plant automation system

Development and implementation of ASA-MIX-1 Concrete Batching Plant Automation System for MEKA, SIMEM, STETTER, ELBA, and ELKON equipment.

Automated control system for a heavy-duty high-pulse generator

Development and implementation of a control system of the Electromagnetic Pulse Generator (EMG), to provide control of EMG and its service systems

Our clients

Our Blog

APCS & RPA: the evolution of automation

Against the background of new achievements in the field of AI and the emergence

Jakusz transferred explosion-proof container “Wiktoria” to Ukraine

Friends, welcome! Today we would like to share good news with you. Our talented colleagues…

XXIX International Exhibition of Defense Industry MSPO

The Defense Industry Fair in Kielce is the place where the most important players

TCH: The game-changing oil processing technology

According to the IEA (International Energy Agency), in the period from 2017 to 2022,

“Green” cement: the latest trends to protect our planet

Thanks to numerous studies by world institutions, we know for sure that CO2, which