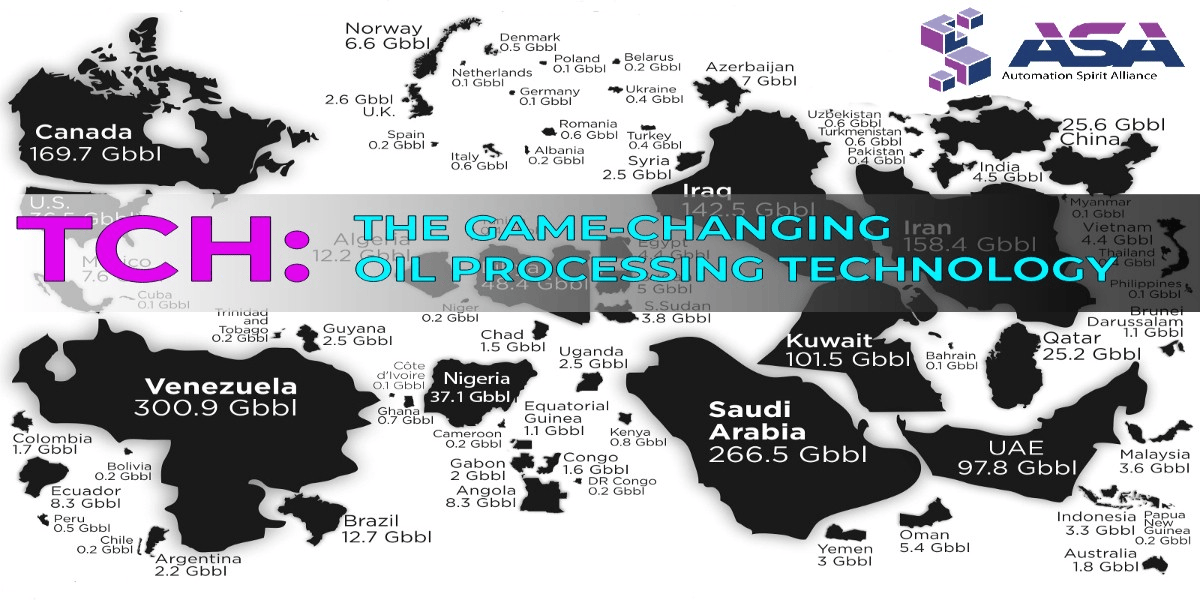

Hi all! Today I would like to talk a little about the global energy market and its trends in oil production. According to the IEA (International Energy Agency), in the period from 2017 to 2022, the share of heavy and super-heavy oil in the total mass of crude oil increased from 8.4 to 12%. This indicates a rather rapid growth of interest in energy resources with complex characteristics. And against the backdrop of OPEC’s decision to limit oil production, in general, it also makes us think about the technological side of the issue.

The low activity in the field of heavy oil production in the past decades was explained by the complexity and high cost of the technologies used. Simply put, the game is not worth the candle, because each barrel produced had to be spent almost as much as it was sold for. However, with the passage of time and technical development, new methods and technologies began to appear that make it possible to significantly simplify and reduce the cost of the extraction process.

TCH-technology — technical breakthrough

One of the breakthroughs in the industry, in which the Automation Spirit Alliance participated, was an oil cavitation technology called TCH-technology. It implies the placement of raw materials in such physical conditions under which the viscosity and density of the oil changes to the required indicators for unimpeded transportation, for example, through a pipeline. At the same time, the number of additional components (such as naphtha), traditionally used to dilute oil during its transportation, is significantly reduced.

At the moment, all the necessary laboratory tests have been carried out on various samples, and the effectiveness of cavitation treatment has been confirmed by the presence of an industrial installation at one of the refineries in South America.

Not only for transportation

It is interesting that this method of processing heavy and super-heavy oil, when changing some parameters, allows achieving another positive effect — increasing the yield of light fractions, which improves the economic effect of using it in refineries.

There are 2 more alternative ways to use cavitators:

- Changing the flash point and the freezing point of fuel oil.

- Preparation of raw materials for use as ship fuel.

Again, in the context of the current situation in the energy market, when interest in heavy oils is increasing, cavitation treatment is becoming more and more attractive at various stages of working with such raw materials.

Promising investment

ASA offers mutually beneficial cooperation in the field of cavitation oil treatment. We have developed several progressive business models for refinery owners, heavy oil companies and interested investors.

To calculate the economic efficiency, get additional information and clarify the terms of cooperation, write to us on LinkedIn, Facebook or contact us in any other convenient way.

And, of course, follow our updates, there are many more interesting publications ahead.